|

Boiler model |

K-140M1 |

K-320M1 |

K-500M1 |

K-720M1 |

K-950M1 |

|

|

Boiler type |

Hot water boiler with moving fire grate, steel, shell boiler |

|||||

|

Nominal heating output (QN), kW |

140 |

320 |

500 |

720 |

950 |

|

|

Minimal heating output (Qmin), kW |

42 |

96 |

150 |

216 |

285 |

|

|

Efficiency, not less than % |

85 |

85 |

85 |

85 |

85 |

|

|

Main used fuels |

Saw dust, wood chips with moist content not exceeding 40% (length not greater than 50mm) . |

|||||

| Other fuels permitted for firing | Fire wood, waste wood, peat and saw dust briquettes, coal | |||||

|

Fuel consumption, kg/h |

62 |

141 |

220 |

317 |

399 |

|

|

Loading opening BxH, mm |

400×450 |

400×450 |

600×620 |

600×620 |

600×620 |

|

|

Combustion chamber |

H, mm |

400 |

500 |

500 |

640 |

700 |

|

B, mm |

640 |

940 |

940 |

940 |

910 |

|

|

L, mm |

1000 |

1640 |

1640 |

2590 |

2590 |

|

|

volume, dm3 (l) |

260 |

770 |

770 |

1558 |

1650 |

|

|

Aerodynamic resistance at QN, not more than, Pa |

180 |

270 |

300 |

320 |

340 |

|

|

Exhaust temperature at boiler flue outlet, °C |

185 |

185 |

185 |

185 |

185 |

|

|

Exhaust volume, m3/h |

585 |

1414 |

2070 |

2860 |

4280 |

|

|

Flue outlet dimensions, mm |

Ø250 |

Ø325 |

Ø350 |

Ø350 |

Ø400 |

|

|

Water operating pressure, bar (MPa) |

6 (0,6) |

6 (0,6) |

6 (0,6) |

6 (0,6) |

6 (0,6) |

|

|

Minimum return water temperature during operation, ºC |

60 |

|||||

|

Maximum permitted operating water temperature, ºC |

110 |

110 |

110 |

110 |

110 |

|

|

Water flow, at Δt =20 ºC, t/h |

6,02 |

13,76 |

21,29 |

30,96 |

40,85 |

|

|

Minimum water flow, t/h |

2,41 |

5,50 |

8,51 |

12,38 |

16,34 |

|

|

Hydraulic resistance at Δt =20 ºC, mm of H2O |

0,014 |

0,134 |

0,144 |

0,282 |

0,430 |

|

|

Water volume in the boiler, m³ |

0,58 |

1,15 |

1,66 |

2,2 |

3 |

|

|

Heat exchange area, m² |

10,3 |

25,8 |

32 |

43 |

73 |

|

|

Connection pipes |

Nominal diameter, mm (inches) |

65 (2½”) |

65 (2½”) |

80 (3″) |

80 (3″) |

80 (3″) |

|

flange diameter, Ø mm |

160 |

160 |

185 |

185 |

185 |

|

|

Mass (not greater than), kg |

2500 |

4900 |

5820 |

7400 |

9700 |

|

|

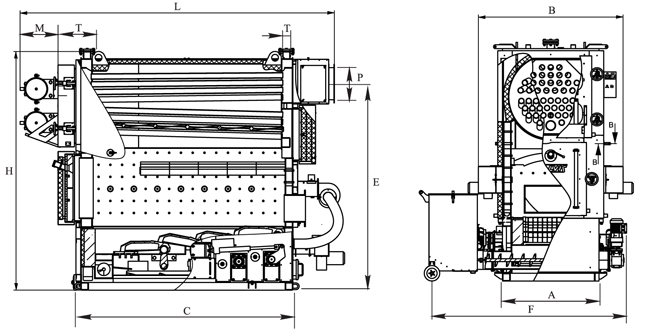

Boiler type |

K-140M1 |

K-320M1 |

K-500M1 |

K-720M1 |

K-950M1 |

|

H, mm |

2105 |

2480 |

2610 |

2765 |

2950 |

|

B, mm |

1300 |

1500 |

1630 |

1630 |

1840 |

|

L, mm |

1900 |

2810 |

2840 |

3640 |

4180 |

|

A, mm |

800 |

1000 |

1400 |

1400 |

1400 |

|

C, mm |

1400 |

2160 |

2620 |

2920 |

3220 |

|

D, mm |

486 |

746 |

846 |

900 |

900 |

|

E, mm |

1534 |

2154 |

2370 |

2520 |

2520 |

|

F, mm |

1500 |

1970 |

2400 |

2400 |

2400 |

|

M, mm |

304 |

374 |

400 |

400 |

400 |

|

P, mm |

Ø240 |

Ø325 |

Ø380 |

Ø380 |

Ø480 |

|

T, mm |

Ø76 |

Ø76 |

Ø89 |

Ø89 |

Ø89 |

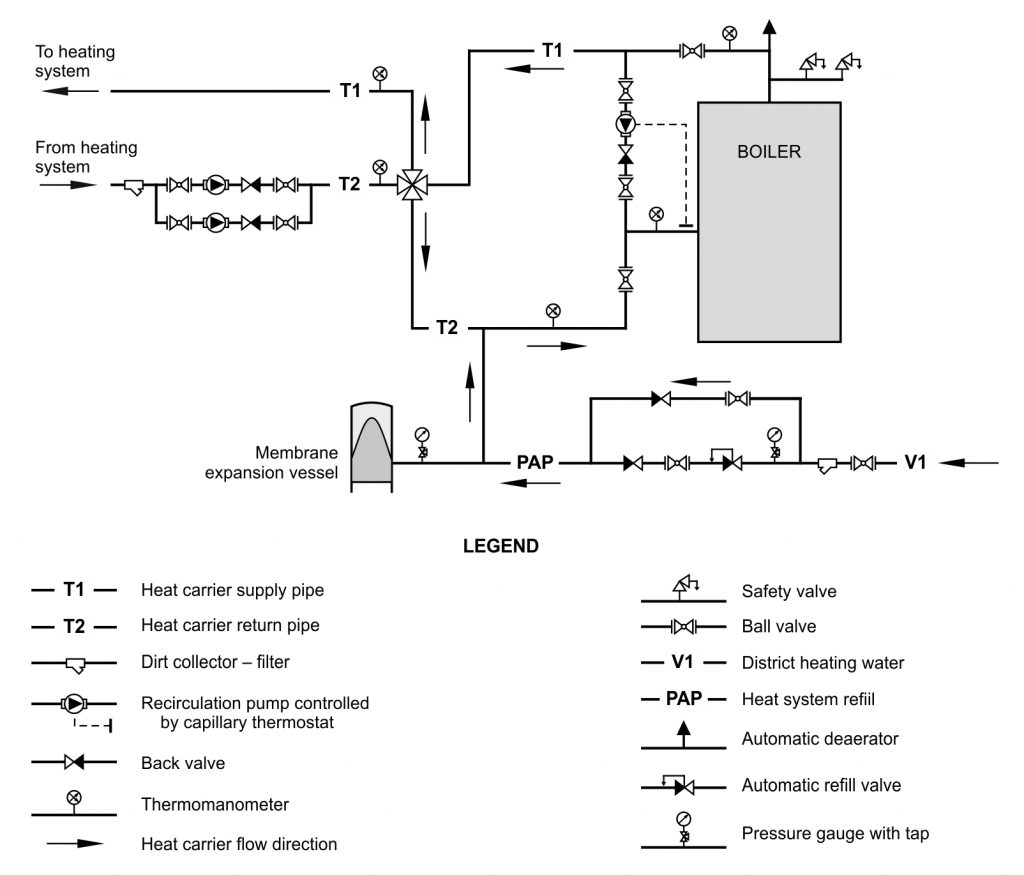

Recommended connection to the heating system diagram: