|

Nominal power, kW

|

12

|

|

Heated area, m² *

|

B class premises 103 – 252

C class premises 55 – 132

|

|

Fuel used

|

wood logs **

|

|

Efficiency (while firing wood logs), %

|

82

|

|

Chamber volume, dm³ (l)

|

42

|

|

Fuel burn time, up to, h ***

|

8

|

|

Wood logs length, up to, cm

|

30

|

|

Water volume in the boiler, l

|

28

|

|

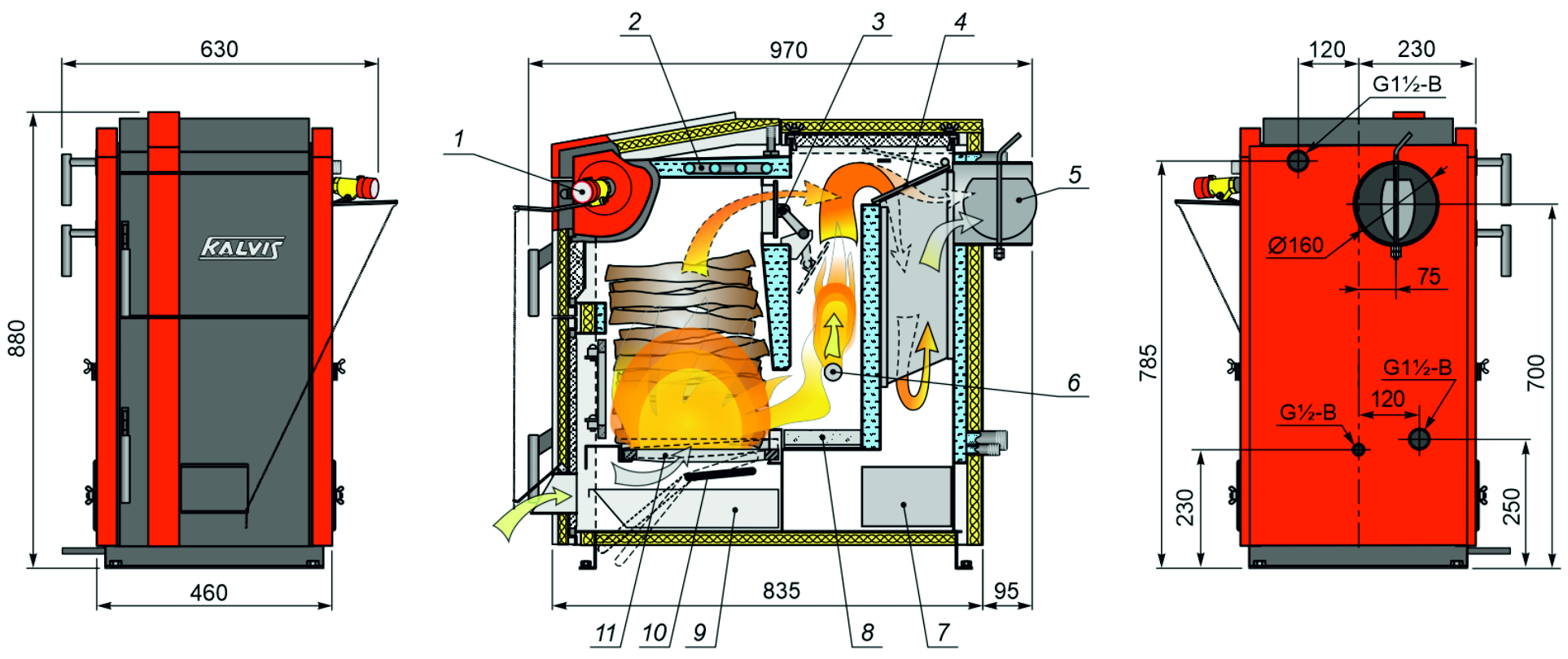

Flue channel diameter, mm

|

160

|

|

Minimal chimney draught, Pa

|

12

|

|

Overall dimensions, HxBxL, mm

|

880x630x970

|

|

Mass (brutto), (±10%), kg

|

222

|

* Energy efficiency according STR 2.01.02:2016.

** It is also possible to use wood waste, sawdust and peat briquettes.

It is not recommended to burn firewood with a moisture content greater than 25%.

*** The burning time of the fuel boiler depends on the type of fuel, humidity, outdoor temperature and other factors.