About Us

UAB „Kalvis“ is one of the largest metal processing companies in Lithuania, employing around 220 skilled workers. Kalvis has an experienced team of designers and technologists who develop and improve heating equipment, design various technological equipment and machinery.

Our main areas of activity are:

1. Biomass boilers design and production:

Domestic Boilers – stoves;

Domestic boilers;

Automated boilers;

Air heating stoves and fireplaces;

Sauna boilers;

70 kW – 2500 kW industrial boilers;

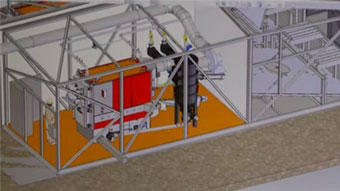

2. Automated heat plant equipment design and manufacture.

3. Design and installation of stationary and container heat plant equipment.

4. Design and manufacture of steel constructions and technological equipment.

5. Manufacture of cabinets and enclosures for power and gas supply and distribution.

6. Steel subcontracting services.

Kalvis manufactures over 100 types of solid fuel fired boilers in series. All of the serial products are tested and improved in Kalvis heating equipment testing laboratories. All our products conform to the requirements for CE marking.

Kalvis products are exported into many countries. Heating equipment sales are successfully growing in Western European countries including Scandinavian countries, Baltic states, Ukraine. There are also references in such countries as Kenya, Moldova, Kazakhstan and others are available.

We perform subcontracting services for companies located in Germany, Sweden, Denmark, Finland and other European countries. We are looking for new partners and possibilities in creating newer and better products