|

Boiler model |

|

K-100M |

K-140M |

K-190M |

K-250M |

K-320M |

K-400M |

K-500M |

K-600M |

K-720M |

K-850M |

K-950M |

K-1250M |

K-1500M |

|

Nominal output |

kW |

95 |

140 |

190 |

250 |

320 |

400 |

495 |

600 |

700 |

850 |

950 |

1250 |

1500 |

|

Efficiency * |

% |

82 |

||||||||||||

|

Fuel used |

|

Saw dust, Chips (length not greater than 50mm), fire wood, waste wood, saw dust or peat briquettes |

||||||||||||

|

Fuel consuption |

Kg/h |

39 |

54 |

74 |

97 |

124 |

155 |

194 |

233 |

280 |

330 |

369 |

486 |

583 |

|

Operating pressure, max./min. |

bar (MPa) |

2,5 (0,25) / 6,0 (0,6) |

||||||||||||

|

Mass |

kg |

800 |

900 |

110 |

2000 |

1900 |

2700 |

3100 |

4100 |

4330 |

4700 |

5100 |

8750 |

9600 |

* Parameters are given using 35 % moisture fuel (Mixture: 35 % humidity chips + 35 % humidity sawdust, proportion 50/50; 2702 kcal/kg).

|

Boiler model |

|

K-100M |

K-140M |

K-190M |

K-250M |

K-320M |

K-400M |

K-500M |

K-600M |

K-720M |

K-850M |

K-950M |

K-1250M |

K-1500M |

|

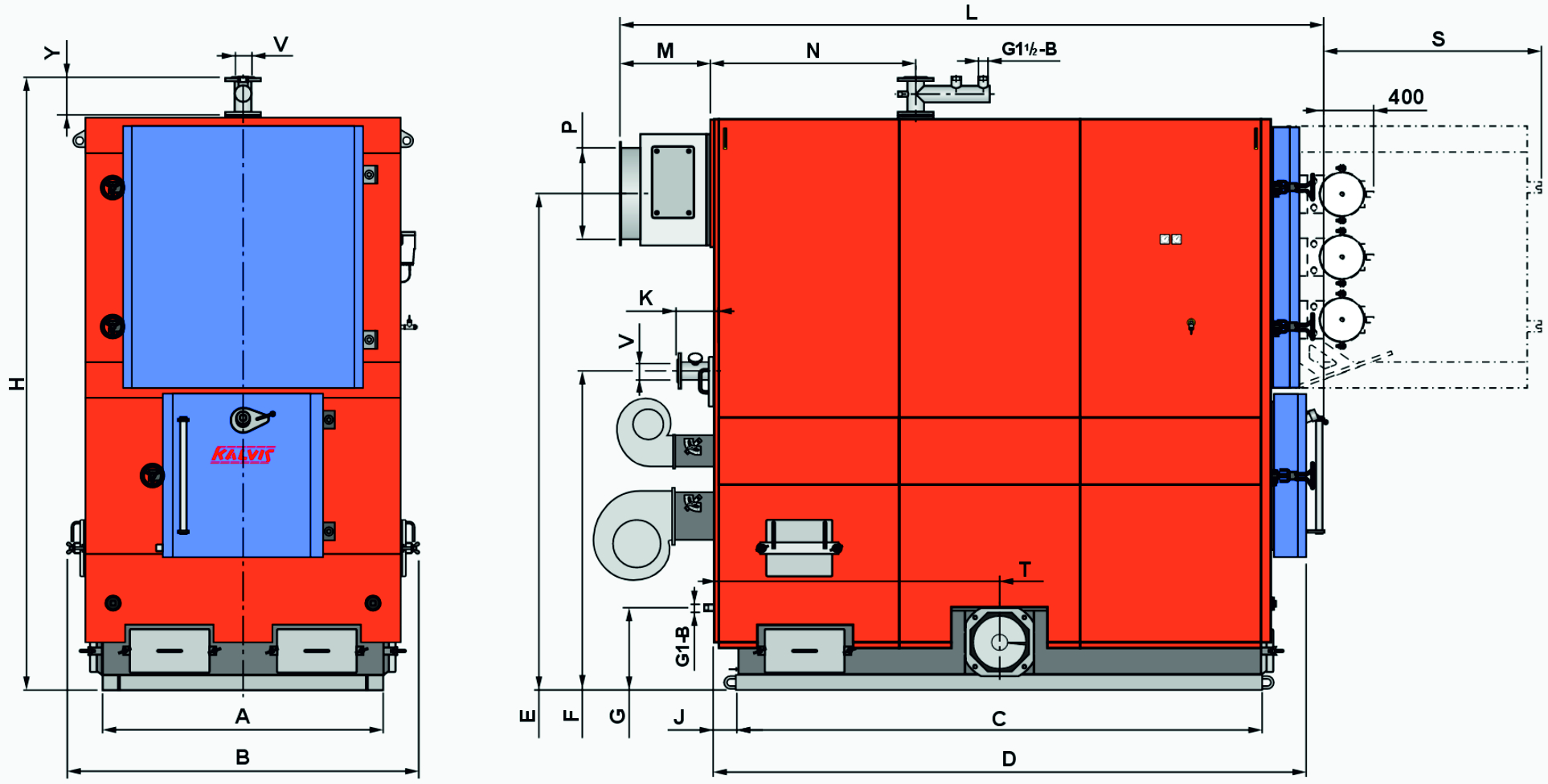

H |

mm |

1940 |

1940 |

2260 |

2260 |

2260 |

2690 |

2730 |

2960 |

2970 |

2970 |

3180 |

3280 |

3280 |

|

B |

970 |

970 |

1140 |

1200 |

1300 |

1470 |

1460 |

1650 |

1610 |

1620 |

1600 |

1860 |

1860 |

|

|

L |

1510 |

1710 |

1830 |

2220 |

2220 |

2460 |

2460 |

2660 |

2990 |

3090 |

3350 |

3700 |

3700 |

|

|

A |

710 |

710 |

890 |

890 |

890 |

1090 |

1090 |

1255 |

1255 |

1255 |

1255 |

1480 |

1480 |

|

|

C |

930 |

1125 |

1195 |

1585 |

1585 |

1505 |

1700 |

1890 |

2085 |

2285 |

2285 |

2760 |

2760 |

|

|

D |

1180 |

1375 |

1520 |

1825 |

1825 |

1815 |

2010 |

2190 |

2375 |

2565 |

2590 |

3120 |

3120 |

|

|

E |

1620 |

1620 |

1900 |

1900 |

1900 |

2240 |

2260 |

2445 |

2455 |

2475 |

2660 |

2610 |

2610 |

|

|

F |

1120 |

1120 |

1300 |

1300 |

1300 |

1505 |

1505 |

1675 |

1675 |

1675 |

1855 |

1685 |

1685 |

|

|

G |

345 |

345 |

345 |

345 |

345 |

355 |

355 |

355 |

355 |

360 |

355 |

430 |

430 |

|

|

J |

100 |

100 |

140 |

140 |

140 |

130 |

135 |

105 |

105 |

105 |

120 |

120 |

120 |

|

|

K |

125 |

125 |

135 |

135 |

135 |

185 |

185 |

220 |

220 |

220 |

205 |

190 |

190 |

|

|

M |

230 |

230 |

235 |

235 |

235 |

530 |

480 |

410 |

530 |

405 |

700 |

490 |

490 |

|

|

N |

340 |

340 |

560 |

560 |

560 |

625 |

675 |

755 |

755 |

825 |

840 |

1060 |

1060 |

|

|

P |

240×240 |

240×240 |

290×290 |

290×290 |

290×290 |

Ø325 |

Ø325 |

Ø380 |

Ø380 |

Ø480 |

Ø480 |

Ø480 |

Ø480 |

|

|

S |

560 |

560 |

700 |

700 |

700 |

850 |

850 |

1060 |

1190 |

1190 |

1060 |

1060 |

1060 |

|

|

T * |

565 |

665 |

725 |

960 |

930 |

910 |

985 |

1020 |

1130 |

1210 |

1225 |

1500 |

1500 |

|

|

V |

Ø65 |

Ø65 |

Ø65 |

Ø65 |

Ø65 |

Ø80 |

Ø80 |

Ø80 |

Ø80 |

Ø80 |

Ø80 |

Ø114 |

Ø114 |

|

|

Y ** |

– |

– |

– |

– |

– |

– |

125 |

235 |

235 |

235 |

235 |

285 |

285 |

* The length of the boiler with the installation of a pneumatic cleaner on the front doors of the heat exchanger (L + 400).

*** During transportation, if it is necessary to reduce the height of the boiler, the boilers Kalvis-500M … Kalvis-1500M can have the hot water branch with flange removed (H – Y).

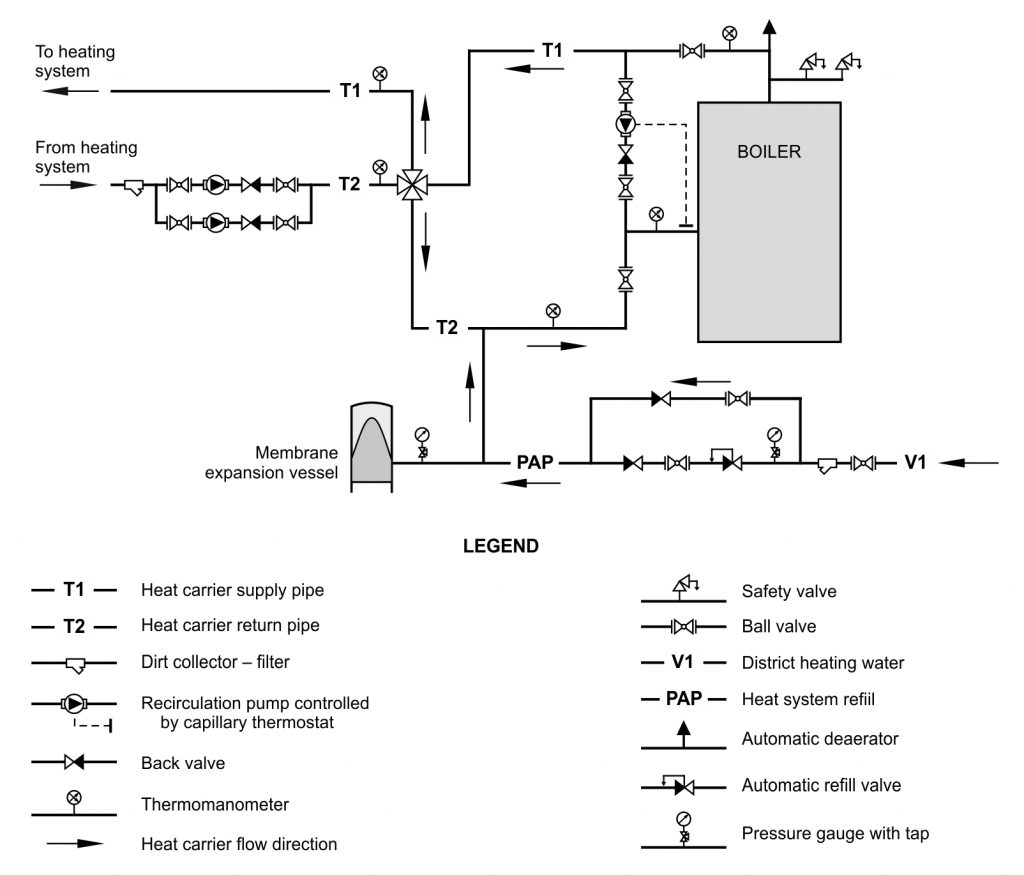

Recommended connection to the heating system diagram: