MULTIPURPOSE PELLET – SOLID FUEL BOILER K-2-12DG (12kw)

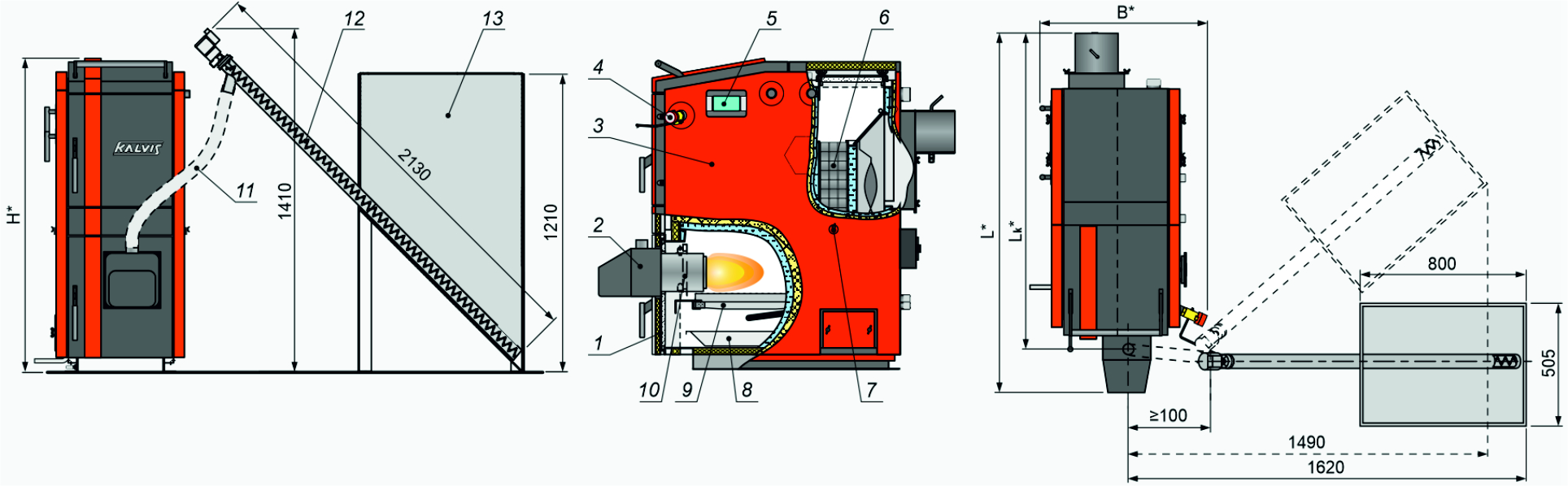

Multipurpose bottom combustion solid fuel boiler with pellets burner

- High efficiency

- Large fuel load

- Fuel is loaded from the front or top

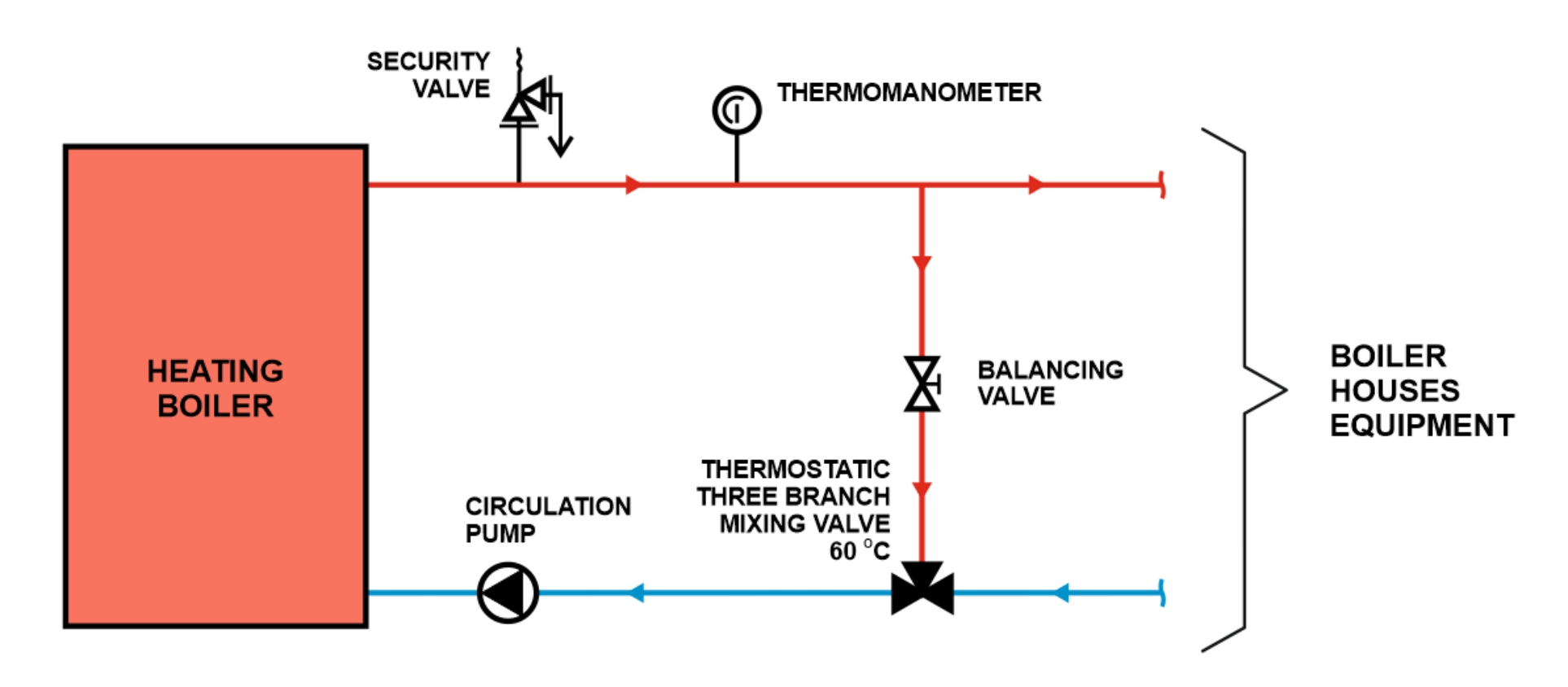

- Automatic adjustment of boiler temperature

- Secondary air supply

- Secondary burning chamber with refractory concrete catalyst

- Smoke exhaust, ignition and draught dampers

- Fire grates shaking mechanism

- Heat exchanger cleaning from both boiler’s sides

- Emergency cooling coil

- Possibility to mount electric heating element

- Possibility to install smoke exhauster

- Easy to modify for firing on solid fuel

- Housing inner wall steel plate thickness – 6 mm

- Warranty for boiler frame – 4 years

BURNER BurnPell X Mini or BurnPell EVO Mini

- Patented fuel mixing inside of burning chamber system

- Control panel contains mounted emergency thermostat

- Automatic ignition, cleaning, combustion control

- Equal electronic output correction

- Automatic start up after power loss

- High combustion efficiency – up to 99 %

- Burner combustion chamber is made of heat proof stainless steel

- Protection against to back fire inside fuel feeding system

- Low el. power usage

BURNER’S CONTROL PANEL S.Control Touch MK2 or S.Control Standard MK2 (touch screen)

- Real time precise operation parameters

- User and service menu

- Programming of weekly operation cycle

- Controls one heating circuit with servo drive, three-way or four-way valve, and hot water preparation

- Controls up to 5 heating circuits with additional modules

- Possibility to control burner via room console using thermostat

- Possibility to control burner via internet, having connected internet module ecoNET

- Possibility to control by lambda probe