|

Description

|

Characteristic

|

|

Nominal output, kW

|

70

|

|

Heated area, m² *

|

B class premises 602…1470

C class premises 322…700

|

|

Fuel used

|

wood logs **

|

|

Efficiency (firing wood logs), %

|

82

|

|

Combustion chamber volume, dm³ (l)

|

467

|

|

Fuel load combustion duration, up to, h.***

|

4…8

|

|

Logs size, not greater than, cm

|

50

|

|

Water volume in the boiler, l

|

198

|

|

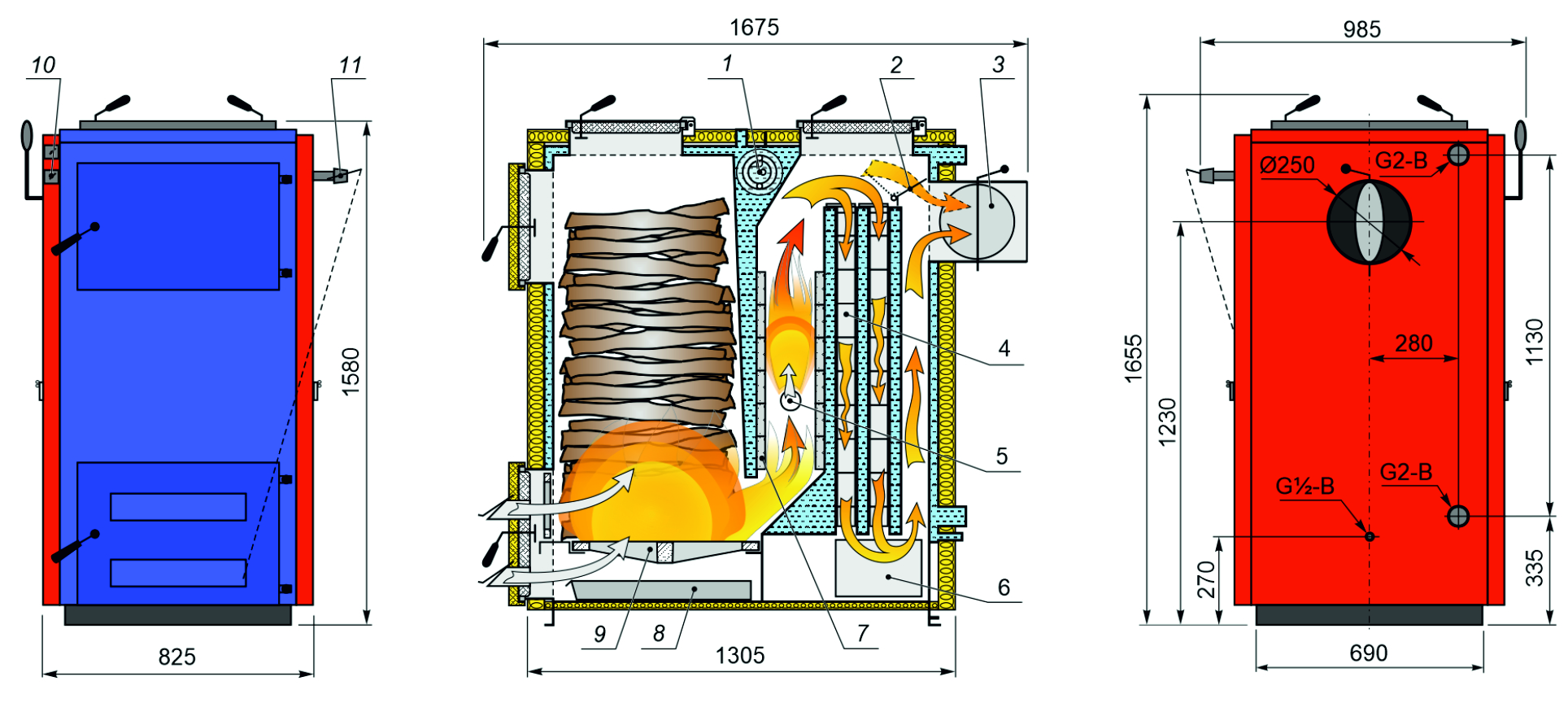

Flue diameter, mm

|

Ø250

|

|

Minimum chimney draught, Pa

|

35

|

|

Overall dimensions, HxBxL, mm

|

1660x985x1675

|

|

Mass (brutto), (± 10 %), kg

|

1066

|

* Energy efficiency according STR 2.01.02:2016.

** It is also possible to use wood waste, sawdust and peat briquettes.

It is not recommended to burn firewood with a moisture content greater than 25%.

*** The burning time of the fuel boiler depends on the type of fuel, humidity, outdoor temperature and other factors.