|

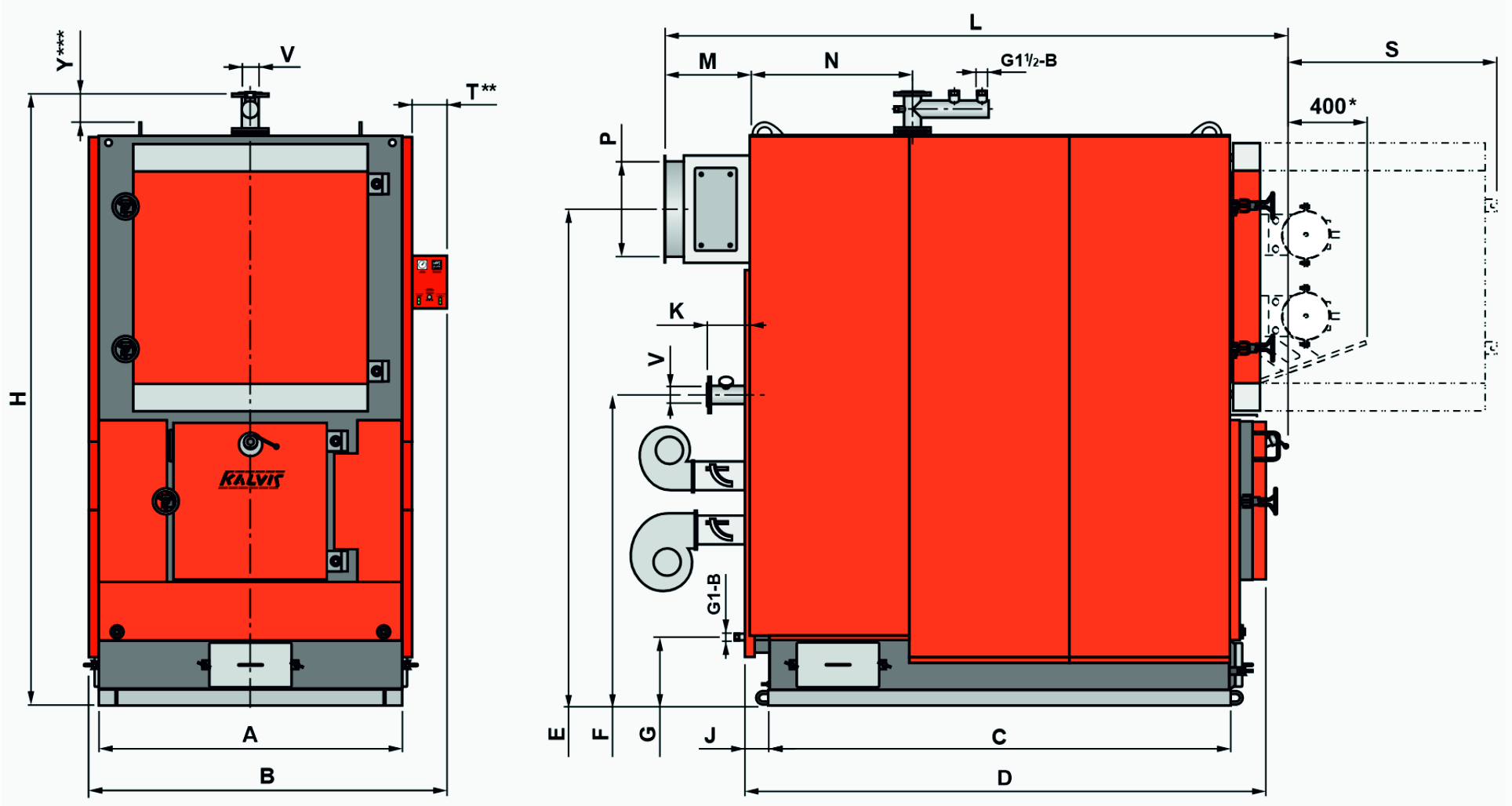

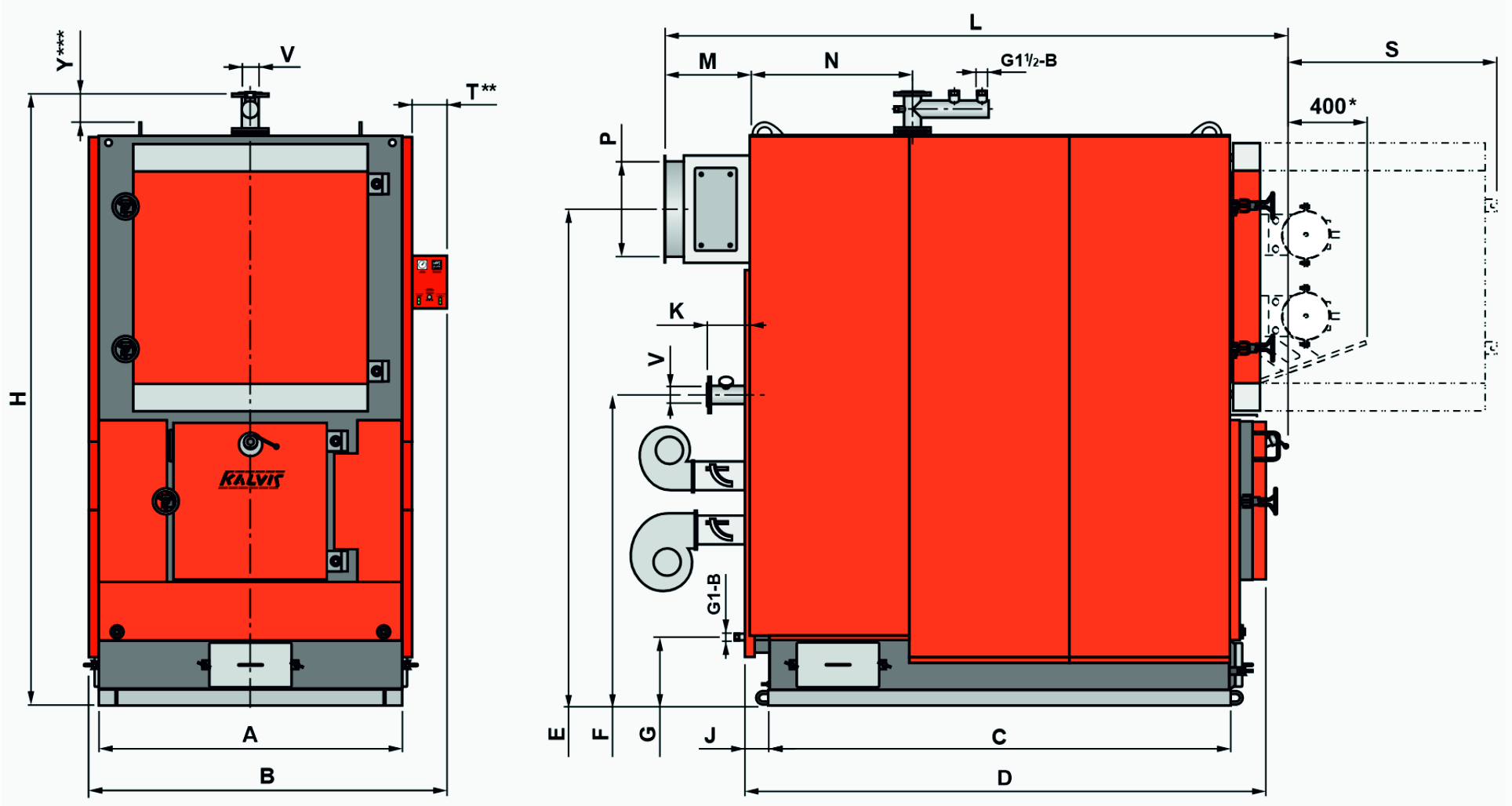

Boiler model

|

|

K-100

|

K-140

|

K-190

|

K-220

|

K-250

|

K-320

|

K-400

|

K-500

|

K-600

|

K-700

|

K-950

|

K-1250

|

|

H

B

L

|

mm

|

1960

1000

1510

|

1960

1000

1710

|

2280

1200

1860

|

2280

1200

2060

|

2280

1200

2250

|

2740

1460

2260

|

2740

1460

2460

|

2870

1460

2850

|

2980

1610

2900

|

2980

1610

3090

|

3180

1840

3150

|

3180

1840

3550

|

|

A

|

710

|

710

|

890

|

890

|

890

|

1090

|

1090

|

1090

|

1255

|

1255

|

1480

|

1480

|

|

C

|

930

|

1125

|

1195

|

1390

|

1585

|

1505

|

1700

|

1890

|

2085

|

2285

|

2370

|

2760

|

|

D

|

1180

|

1385

|

1435

|

1680

|

1825

|

1815

|

2000

|

2190

|

2375

|

2565

|

2700

|

3095

|

|

E

|

1620

|

1620

|

1920

|

1920

|

1920

|

2240

|

2240

|

2364

|

2445

|

2475

|

2545

|

2545

|

|

G

|

365

|

365

|

365

|

365

|

365

|

365

|

365

|

345

|

355

|

355

|

350

|

350

|

|

F

|

1120

|

1120

|

1300

|

1300

|

1300

|

1490

|

1490

|

1640

|

1670

|

1670

|

1605

|

1605

|

|

J

|

100

|

100

|

100

|

120

|

100

|

110

|

110

|

110

|

105

|

105

|

120

|

120

|

|

M

|

260

|

260

|

270

|

270

|

270

|

380

|

380

|

380

|

400

|

400

|

395

|

395

|

|

P

|

240×240

|

240×240

|

290×290

|

290×290

|

290×290

|

Ø325

|

Ø325

|

Ø380

|

Ø380

|

Ø480

|

Ø480

|

Ø480

|

|

S

|

560

|

560

|

700

|

700

|

700

|

850

|

850

|

1060

|

1190

|

1190

|

1060

|

1060

|

|

T **

|

130

|

130

|

130

|

130

|

130

|

180

|

180

|

180

|

180

|

180

|

180

|

180

|

|

V

|

Ø65

|

Ø65

|

Ø65

|

Ø65

|

Ø65

|

Ø80

|

Ø80

|

Ø80

|

Ø80

|

Ø80

|

Ø80

|

Ø80

|

|

Y ***

|

–

|

–

|

–

|

–

|

–

|

130

|

130

|

235

|

235

|

235

|

235

|

235

|

* The length of the boiler with the installation of a pneumatic cleaner on the front doors of the heat exchanger: L + 400

** During transportation, if it is necessary to reduce the width of the boiler, the electric control panel can be removed: B – T

*** During transportation, if it is necessary to reduce the height of the boiler, the boilers Kalvis-320 … Kalvis-1250 can have the hot water branch with flange removed: H – Y